NOMURA MACHINE TOOLS: HORIZONTAL BORING MILLS

NOMURA STRESSES HIGH RIGIDITY, ACCURACY & POWER.

NOMURA COMES WITH THREE SERIES:

When it comes to buying a new horizontal boring mill ,we know that you are looking for a machine tool that is built to handle the most demanding jobs in your shop. As the old boring mills are fading away, we looked for and found Nomura as a great choice for a horizontal boring mill replacement.

We became a Nomura Horizontal Boring mill distributor because Nomura meets our stringed qualifications in a CNC machine tool that we sell. It is very important to us that we sell quality machine tools to our customers.

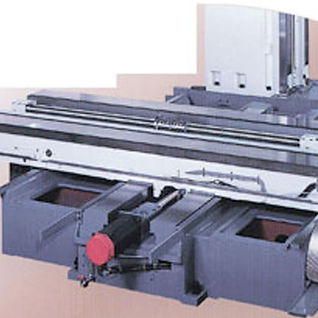

NOMURA CNC TABLE TYPE HORIZONTAL BORING AND MILLING MACHINE

The Nomura CNC Table Type Horizontal Boring Mill and Milling machine is the top-of-the-line CNC machine that achieves ease of operation and meets the high level of requirements of today's machine tool industry.

This horizontal table type horizontal boring and milling machine sets itself apart from others as a high precision boring mill who has attained the finest technology that has been refined over the years.

The heavy -duty cutting is achieved with an integrated design that takes advantage of the rigidity of each main component. Find out why we think Nomura beats its competitors in table-type horizontal boring mills for sale.

Below read how these table-type horizontal boring mills are build with an excellence few achieve.

-

The spindle undergoes more than 20 processes from nitriding to super finishing, which ensures long years of use with minimal wear.

-

The adoption of the nose type spindle head allows better accessibility which provides rigidity and permits heavy-duty cutting.

-

By attaining higher spindle speeds and faster rapid feeds, the workpiece cutting time have been shortened; this greatly improves your productivity.

-

By employing a high output AC 18.5/22 kW(25/30HP) motor (30 min./rating) for the rotation drive of the spindle, 2 stage step-less speed change over a wide range is obtainable.

-

The main bearings of super high rigidity and precision have been used to assure high precision in the spindle rotating system.

-

The elaborate spindle preparation involves more than twenty processes, from nitride heat-treatments to super-finish grinding, so as to the assure wear and deterio-ration resistance.

-

And finally, since the bearing components of the spindle are equipped with mist lubrication, and the outer spindle and motor flange employ an oil-jacket cooling system, they are free from head and distortion caused by friction, and support high speed cutting and heavy-duty machining.

HB Series: Horizontal Boring & Milling Machine: HB-135 SERIES:

HBA-135 Series CNC Table Type Horizontal Boring and Milling Machine

• 5.3" spindle diameter

• Oversized large diameter ball screws and feed motors

• Nitrided hardened, ground and hand-lapped spindle (HRC 67+)

• Extra-large spindle bearings with oil-mist cooling device

• Full CNC controlled B axis rotary table with double warm

• Three ranges of geared-headstock with 60HP spindle motor (2,930 Ft. Lbs)

• The bed, the saddle, the column and the table are of high grade FC 300 iron

• All the slideways are hardened and ground

• The mating surfaces are coated with a fluorine-resin and forced lubricated

NOMURA: HB-110 SERIES

HB SERIES FEATURES: UNPARALLELED QUALITY

RIGID BED & SADDLE

OPERATOR-FRIENDLY CONTROLLER

ATC MAGAZINE

HAND SCRAPED

NOSE-TYPE HEADSTOCK, EXTRA REACH TO WORKPIECE

BUILT-IN CHIP CONVEYOR

HB -110 Series: CNC Table Type Horizontal Boring & Milling Machine:

-

Since 1917, Japan’s most oldest and most experienced manufacturer puts the complete HBM package together.

-

All the major components are cast from the highest grade of iron, designed as a one-piece bed with the rational-rib approach and overly heavy walls and wide box ways.

-

Hardened and then hand-scraped or machined to perfection.

-

Taking a six month and twenty-step process, nitride hardened, ground and hand-lapped spindle ensures the Nomura spindle has ideal hardness and finish. It is 300% straighter than even the Japanese Industrial Standards ( JIS ) allow.

-

The Fanuc controller and oversized servo motors, ballscrews, bearings, gears, and all the internal components meet the highest levels of the JIS quality requirements.

-

A full array of optional accessories such as enlarged ATC magazines, facing and contouring heads, secondary rotary tables, and Probes, etc. are available.